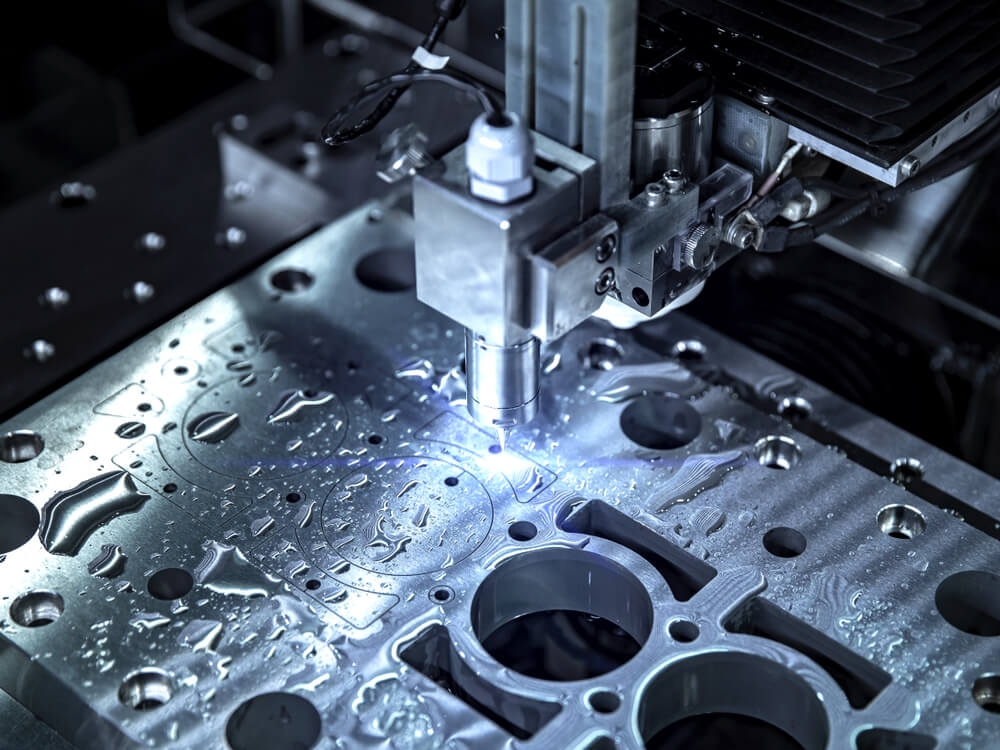

AccuTrex Products utilizes waterjet technology to manufacture parts for the architectural and public art industries. Waterjet cutting is optimal for this industry because it enables our company to cut through thicker materials and irregular shapes, while still retaining speed and accuracy. We are also able to utilize this practice for a variety of materials. Waterjet cutting is an ideal option for unique, custom designs (prototypes and short runs).

Materials Include:

- Brass

- Copper

- Titanium

- Steel

- Alloys

- Stainless steel

- Composites

- Wood

- Plastics

- Glass

- Granite

- Marble

- Natural tile

- Natural stone

- Engineered tile

- Engineered stone

- Ceramic tile

Architectural and decorative waterjet cutting benefits:

- Accurate tolerances

- No heat-affected zones

- Precise CNC cuts to +/-.005*

- Improved productivity

- Potentially less waste-common wall cutting

- Easily makes complex cuts and irregular shapes

- Perfect for prototypes and small runs

- Near net shape production

- Fast setup for production runs

- Smooth, precise edges*

- No burrs

- Repeatability

- Multiple-head cutting

- No tooling charges

- Uniform cuts

- Eliminates secondary operations/finishing

*depending on thickness and type of material

AccuTrex Products is an ISO 9001 and AS9100 registered, veteran-owned small business.