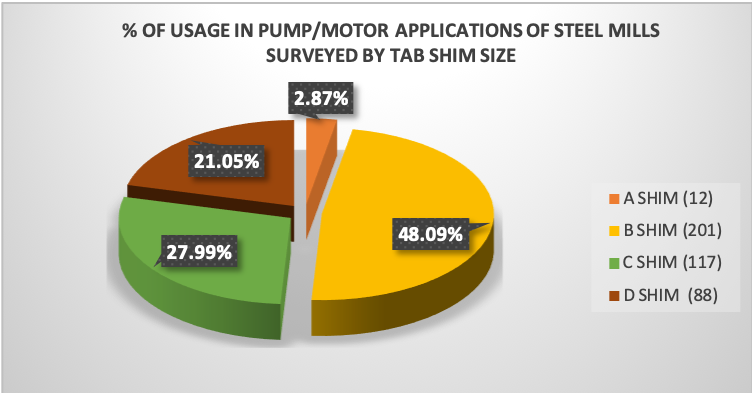

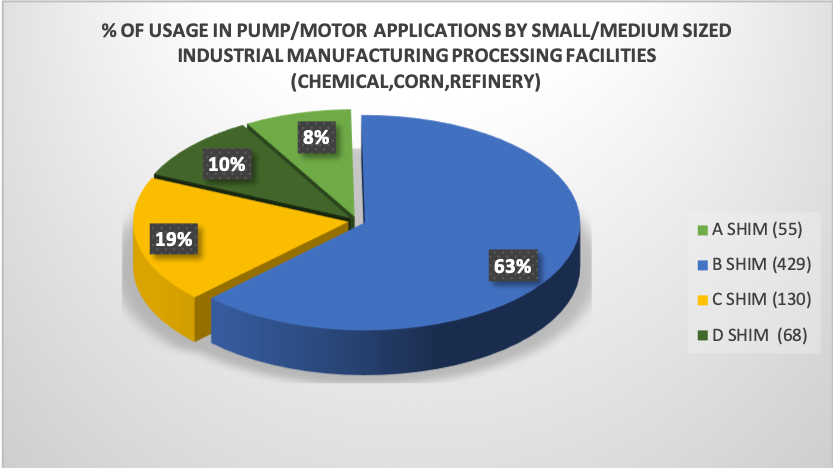

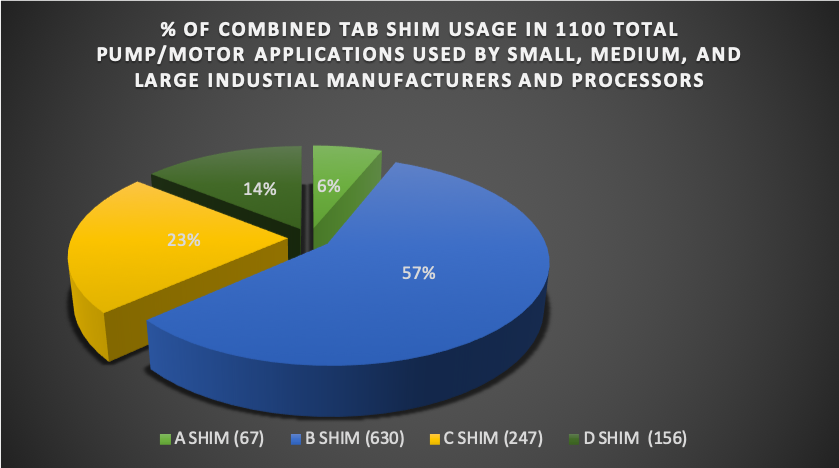

AccuTrex Products, conducted a market study of tab shim usage by small, medium, and large industrial manufactures and processors. In data compiled over an 8 year period, we found 85.81% of shimmed equipment used a combination of standard “A”, “B”, or “C” tab shims.

Many of these applications were miss-matched, where a “convenient” job-site shim was used improperly causing “soft foot” at the base of the unit that may lead to excessive machine vibration and cavitation resulting in equipment damage. Why risk damage to valuable equipment with incorrect shim installations when you can take the guess work out with the UNIVERSAL SHIM™?